Recent Posts

Quality control takes a very important role in JB factory . It's activities covered by Input, Process and Final Control guarantee all the products quality.

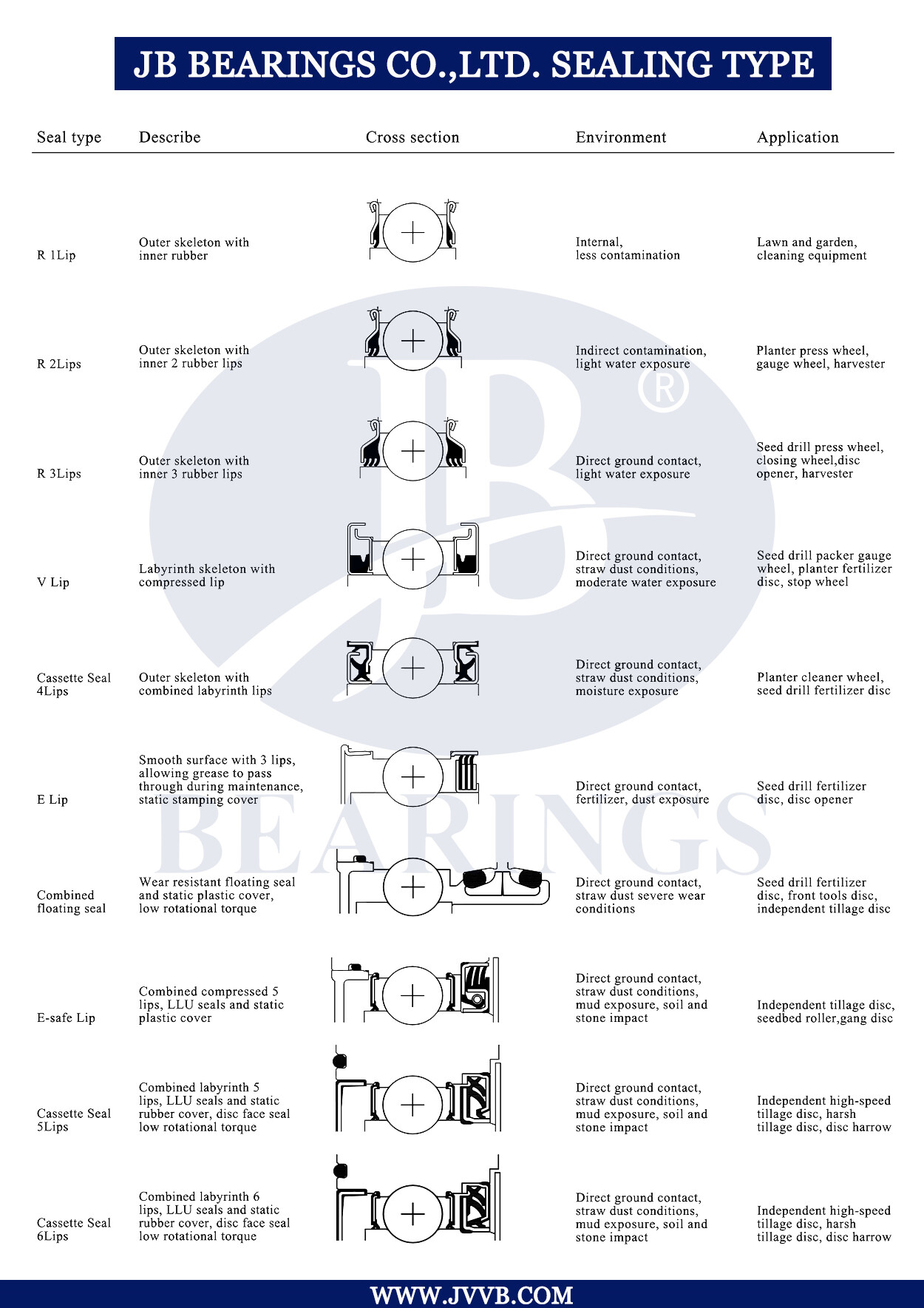

The quality level of JB bearing is based on following :

Technical support

Product production

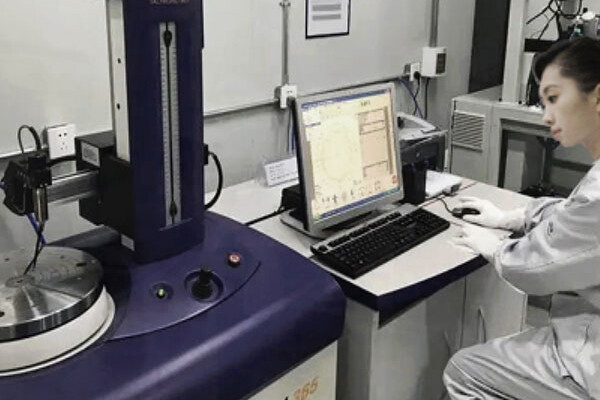

Product testing

Long-term certification of suppliers

JB Bearing quality process control

In the manufacturing industry, quality is the lifeline of enterprises, especially for the bearing industry.

The quality of mechanical equipment directly affects the performance and safety of mechanical equipment. Therefore, the quality of the bearing Strict control of the process is an important hand to ensure product quality and improve customer satisfaction.

1. Quality control of raw materials

Raw materials are the first step in bearing quality, only high-quality raw materials, in order to produce high-quality the bearing. Therefore, strict quality inspection and control of raw materials is essential Yes. This includes a comprehensive examination of the chemical composition, physical properties, surface quality and so on of raw materials Inspection and evaluation to ensure compliance with standards and design requirements.

2. Quality control of the production process

In the production process, each step of the process should be strictly controlled. From the cutting of raw materials, into type, heat treatment, grinding, assembly and other links need to be strictly in accordance with the operating procedures and real-time monitoring of the quality parameters in the production process to ensure that every link is in line with quality quantity requirement.

3. The quality control of the testing process

After the end of production, strict quality testing should be carried out on bearings. This includes the ruler of the bearing inch, accuracy, surface quality, mechanical properties and other comprehensive testing to ensure product quality to meet customer requirements. For unqualified products, they should be reworked or scrapped to avoid bad products entering the market.

4. Quality management system construction

Establishing a perfect quality management system is the basis of ensuring the bearing quality process control. This includes develop strict quality standards, operating procedures, inspection procedures, etc., and ensure that these provisions are met to effective execution. At the same time, it is also necessary to continuously improve the quality awareness and skill level of employees. Enhance the quality management capability of the enterprise.

5. Continuous improvement and optimization

Bearing quality process control is a process of continuous improvement and optimization. Through collection and analysis Production process data, find the existing problems and deficiencies, targeted improvement and Optimize and continuously improve production efficiency and product quality. At the same time, also to the development of the industry dynamics And customer needs change, timely adjust the quality control strategy to meet the constant changes in the market.

LEAVE US A MESSAGE

If you have any questions, please fill out the form to contact us, and our customer service will reply to you within 24 hours!