Recent Posts

The R & D team of JB BEARINGS Bearings focuses on the design of products to meet the specific applications of customers, the development of innovative, cost-effective bearing solutions to meet the needs of the industry. The product performance standards and reports are based on fact-based customer feedback and the feedback of the equipment itself. Using advanced testing equipment, JB BEARINGS can quickly and precisely verify the design concept to ensure the faster launch of new products.

JB BEARINGS R & D Team Focus On

- Product Development / Material research.

- Product testing - Product performance analysis.

- Optimization of bearing properties with the help of advanced computational tools.

Multiple Tests Guarantee Quality

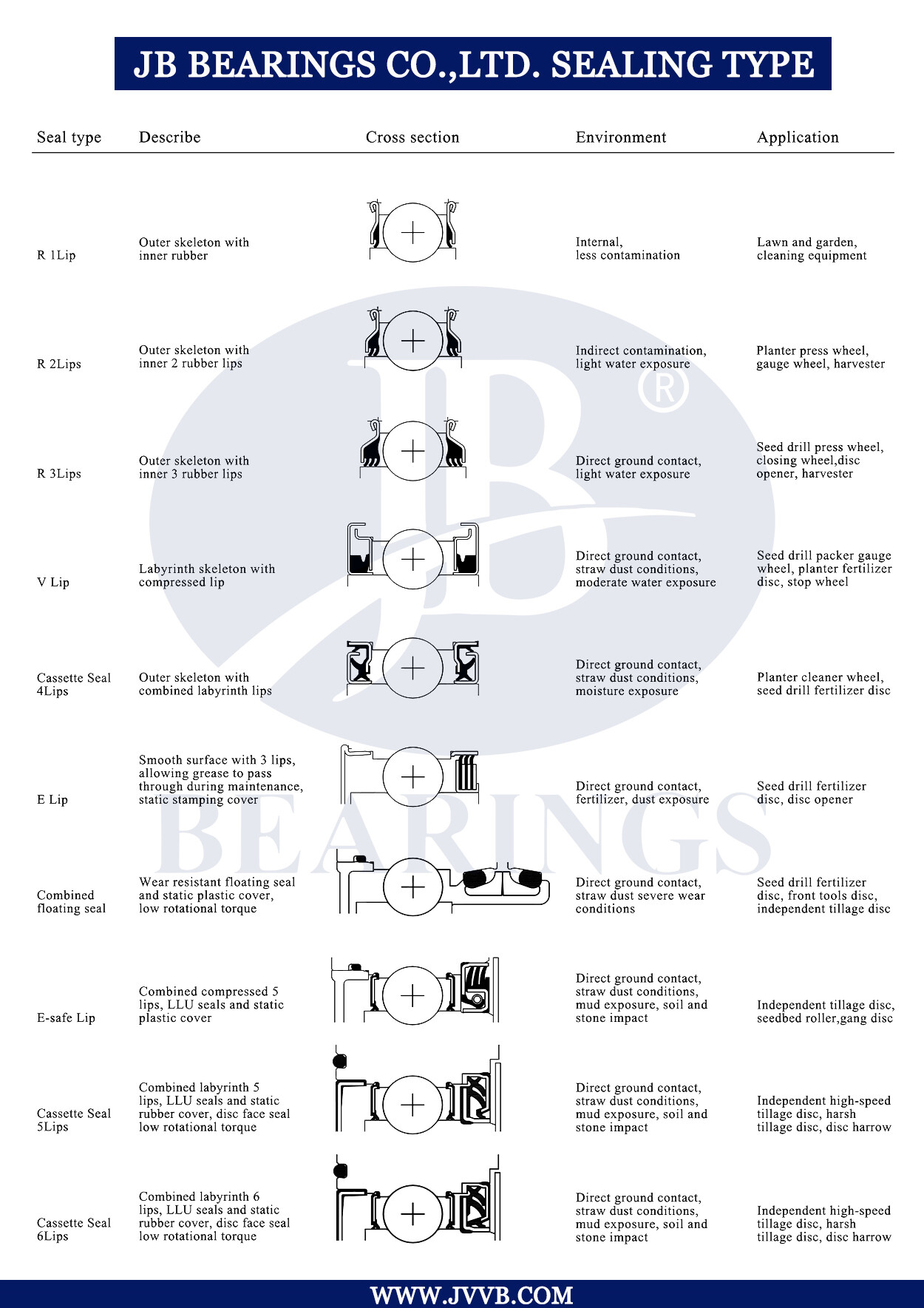

Repeated laboratory tests under extreme conditions allow field tests of several agricultural production cycles to be simulated in a very short period of time, and various sealing systems are tested day and night in harsh testing machines to simulate various use conditions of agricultural machinery, which means that the sealing performance of each batch of products can be quickly verified. Many different technical solutions can be validated during the project development phase, which means faster development cycles and faster product delivery. At the same time, we also maintain close communication with agricultural equipment manufacturers and farms throughout the year, and the final verification of the sealing system through field testing.

LEAVE US A MESSAGE

If you have any questions, please fill out the form to contact us, and our customer service will reply to you within 24 hours!