Recent Posts

Agricultural machinery housing bearing is a common agricultural machinery parts, its damage has been troubling agricultural machinery users. This not only affects the normal operation of agricultural machinery, but also shortens the service life of bearings. In order to solve this problem, we have an in-depth understanding of the damage of Agricultural machinery housing bearings and take effective preventive measures.

First, agricultural machinery bearing damage

The damage of agricultural machinery bearing with seat mainly refers to the flaky disengagement of the bearing surface. This damage usually occurs when the bearing bears a large load, such as farm operations, transportation, and so on. Such damage may occur when the bearing inner ring, outer raceway surface or rolling surface is affected by excessive load, non-parallel linear installation, torque load, pollutant intrusion, water seepage and other factors.

Second, agricultural machinery bearing damage

1. Excessive load: When the load of agricultural machinery bearing is too large, it is easy to cause fatigue damage to the bearing surface, and then produce a scaly detachment.

2. Poor installation: If the installation is not correct, the bearing is not in a parallel linear state, which will cause the raceway surface and rolling surface to be subjected to uneven stress, thus accelerating the damage of the bearing.

3. Torque load: When agricultural machinery bearing bearing is subjected to torque load, it is easy to produce additional stress, causing damage to the bearing surface.

4. Pollutant intrusion: dust, soil and other impurities enter the bearing inside, will aggravate the bearing surface wear and corrosion.

5. Water seepage: If the bearing is in a humid environment for a long time, the water will penetrate into the bearing, causing corrosion and wear.

6. Poor wetting: If the lubrication is improper or the lubrication fluid is not suitable, it will lead to increased bearing friction, thus accelerating the wear of the bearing.

Seven. Agricultural machinery bearing side backlash is not appropriate: too much side backlash makes the bearing susceptible to external impurities, and too small side backlash will affect the rotating flexibility of the bearing, thereby accelerating the wear of the bearing.

8. Damage caused by poor precision, uneven stiffness of agricultural machinery bearing box, large shaft deflection value, rust, corrosion point, scratch, impression (surface deformation).

Third, agricultural machinery bearing damage countermeasures

In order to effectively prevent the scaly detachment of agricultural machinery bearing, we can take the following measures:

1. Check the size of the load and the agricultural machinery bearings used in the laboratory again: ensure that the load borne by the agricultural machinery bearing is within the specified range to avoid excessive load causing damage to the bearing. At the same time, simulation tests were carried out in the laboratory to better understand and master the performance of agricultural machinery bearing under different load conditions.

2. Improved installation method: When installing Agricultural machinery housing bearings, it is necessary to ensure that they are in a parallel linear state to avoid stress concentration. At the same time, professional installation tools and processes are used to ensure installation quality and safety.

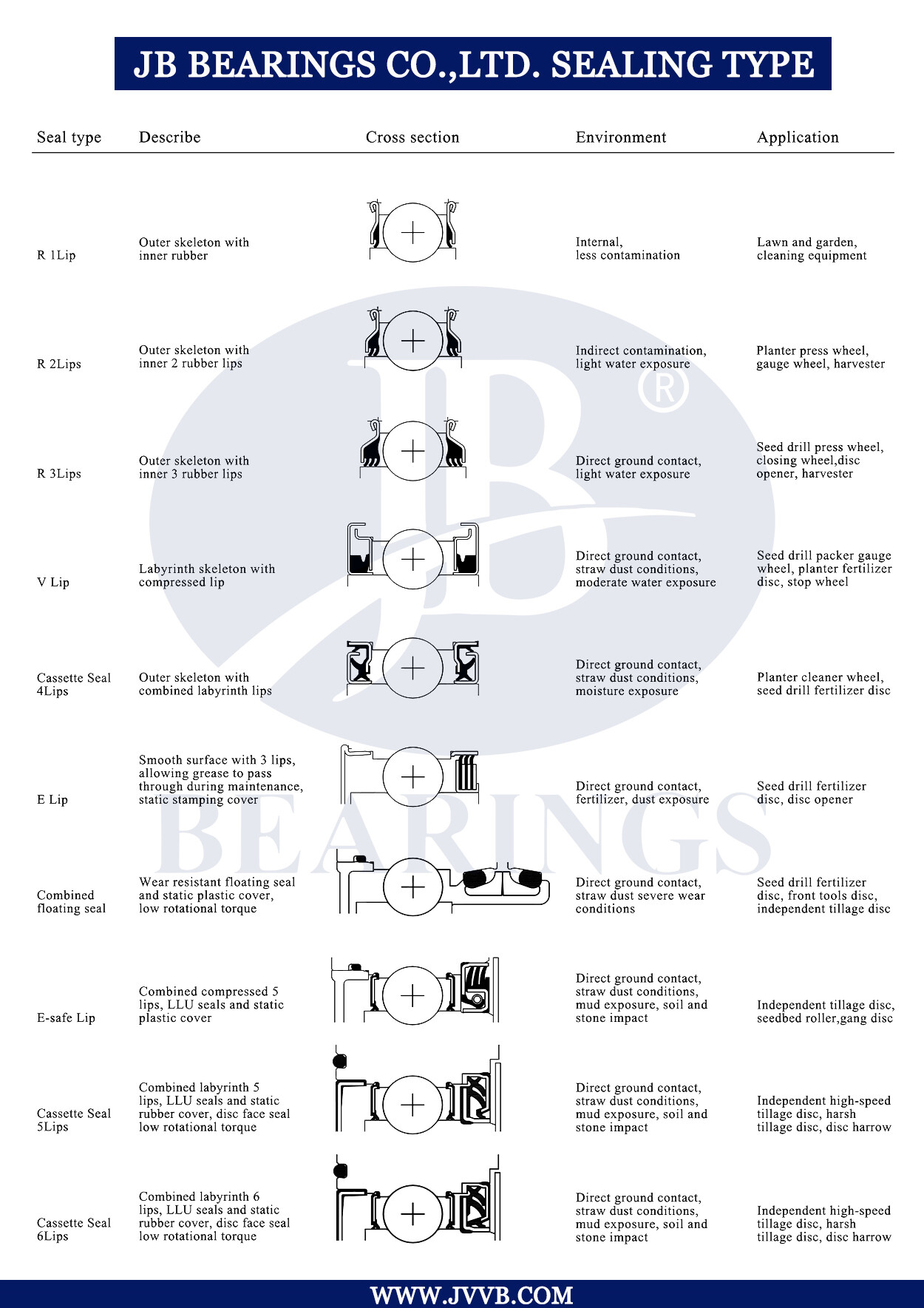

3. Improved sealing equipment, anti-rust treatment during shutdown: By improving sealing equipment, such as the use of high-performance seals and lubricants, you can effectively prevent dust, moisture and other impurities into the bearing interior. At the same time, anti-rust treatment is carried out during shutdown to avoid corrosion problems in a humid environment for a long time.

4. Application of appropriate viscosity lubricants, improved wetting method: Choosing the right lubrication fluid and wetting method can effectively reduce friction and wear. For example, the use of circulating lubrication systems can better protect bearing internal components and reduce friction and wear.

5. Check the accuracy of shaft and bearing seat of agricultural machinery: The accuracy of shaft and bearing seat of agricultural machinery has an important impact on the normal operation of bearings. By checking the accuracy of the shaft and the bearing seat of the agricultural machinery, possible problems can be found and solved, such as the bending deformation of the shaft.

6. Check side backlash: Side backlash is one of the important factors affecting bearing rotation flexibility. By checking whether the side clearance is moderate, it can avoid affecting the bearing rotation flexibility due to too small side clearance or being affected by external impurities due to too large side clearance.

LEAVE US A MESSAGE

If you have any questions, please fill out the form to contact us, and our customer service will reply to you within 24 hours!